The process controller function enables a measured process variable to be controlled to a reference (setpoint) value.

Controller structure

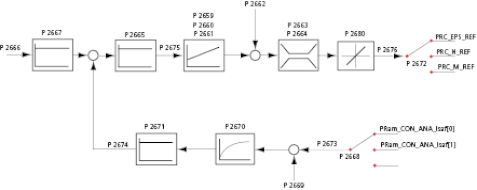

Bild: Schematic of process controller

Vorgehensweise: Process controller setup

Downstream of the control variable limiter there is another limitation which limits the changes to the control variable per sampling segment. By way of field parameter

P 2680 CON_PRC_Rate Limiter the limitation of the control variable steepness per millisecond can be parameterized. By way of index (0) the limitation is active in standard process controller operation. By way of index (1) reduction of the I-component is activated (see table).

With P 2672 CON_PRC_OUTSEL = 3 the process controller delivers an additive position reference value. The rate limiter limits the possible control variable change. The control variable change each time interval by the process controller results in a speed change on the motor shaft.

Example

The amount of the process controller to change the speed on the motor shaft should not be higher than 100 revolutions per minute. To achieve this, the value of parameter P 2680 (0) CON_PRC_Rate Limiter must be parameterized with a value corresponding to the user unit. The unit of this parameter is [x/ms]. The x stands for the respective unit of the process controller output variable. In this example the control variable (additive position reference) has the unit "Increments"

(see also parameter P 270 MPRO_FG_PosNorm). This parameter indicates how many increments correspond to one motor revolution.

Conversion from [rpm] to [Inc/ms]

nchange = 100 rpm

P 0270 MPRO_FG_PosNorm in inc/rev

Internal position resolution = 1048576 inc/rev (default)

To reduce the I-component, the same method is applicable

P 2680(1) CON_PRC_Rate Limiter(1) [Inc/ms]).

P 2680 CON_PRC_Rate Limiter = n change*1048576 *1/60000

P 2680 [Inc/ms] = 100 [rpm] * P 0270 [Inc/rev] * 1/60 [min/s*] * 1/1000 [s/ms]

Scope signals for visualization of the process control loop

| No. | Parameter name | Function |

|---|---|---|

| P2675 | CON_PRC_Cdiff_ | Control difference of the process controller |

| P2666 | CON_PRC_RefVal | Process controller reference |

| P2673 | CON_PRC_Raw_ActVal | Actual value of the selected actual value source ) |

| P2674 | CON_RPC_Actval | Momentary actual value of the process controller; after filtering and scaling |

| P2676 | CCON_PRC_Outval | Process controller control variable |

Tabelle: Scope signals

Process controller parameters

| P. no. | Parameter name | Function |

|---|---|---|

| P2659 | CON_PRC_Kp | P-gain of the process controller |

| P2660 | CON_PRC_KP_SCALE | Adaptation of the P-gain |

| P2661 | CON_PRC_Tn | Process controller integral-action time |

| P2662 | CON_PRC_REFOFFSET | Offset for the process controller output |

| P2663 | CON_PRC_LIMPOS | Positive process controller limitation |

| P2664 | CON_PRC_LIMNEG | Negative process controller limitation |

| P2665 | CON_PRC_CDIFF_SIGN | Adaptation of control difference sign |

| P2666 | CON_PRC_REFVAL | Process control reference value |

| P2667 | CON_PRC_REFSCALE | Scaling factor for the process controller reference |

| P2668 | CON_PRC_ACTSEL | Selection of the actual value source |

| (0) | ISA00 | Analog input 0 |

| (1) | ISA01 | Analog input 1 |

| (2) | Fieldbus | Field bus parameter CON PRC_ACTVAL_Fieldbus-ID 2677 |

| (3) | REFSPEED | Actual speed [rpm] |

| (4) | REFPOS | Actual position [increments] |

| (5) | ISQREF | This function requires further parameter settings – see "Rack and Pinion Control (RPDC)". (Only on request) |

| P2669 | CON_PRC_ACTOFFSET | Offset for actual value calibration |

| P2670 | CON_PRC_ACTTF | Filter time for actual value filter |

| P2671 | CON_PRC_ACTSCALE | Scaling for the filtered process actual value |

| P2672 | CON_PRC_OUTSEL | Selection parameter for the process controller output |

| (0) | OFF | OFF |

| (1) | REFTORQUE | Additive torque reference |

| (2) | REFSPEED | Additive speed reference |

| (3) | REFPOS | Additive position reference |

| (4) | MOPRO_Output to P 2678 | Value for MotionProfile (CON_PRC_OUTSEL_MOPRO – ID 2678) |

| P2673 | CON_PRC_RAW_ACTVAL | Actual value of the selected actual value source |

| P2674 | CON_PRC_ACTVAL | Momentary actual value of the process controller after filtering and scaling |

| P2675 | CON_PRC_CDIFF | Control difference of the process control loop |

| P2676 | CON_PRC_OUTVAL | Process controller control variable |

| P2677 | CON_PRC_ACTVAL_FIELDBUS | Parameter to which an actual value can be written from the field bus |

| P2678 | CON_PRC_OUTSEL_MOPRO | Parameter to which the control variable can be written in order to be subsequently used in the motion profile. |

| P2679 | CON_PRC_RefReached | "Reference reached" window |

| P2680 | CON_PRC_RateLimiter | Steepness limitation of the control variable |

| (0) | RateLimiter | Steepness limitation in standard process controller operation; unit: [Userunits/ms] |

| (1) | RateLimiter | Steepness limitation to reduce the process controller I-component; unit: [Userunits/ms] |

| P2681 | CON_PRC_CtrlWord | Control word of the process controller |

| (0) | PRC_CTRL_ON | Bit 0 = 1: START; switch on process controller |

| (1) | PRC_CTRL_ResetIReady | Bit 1 = 1: Reset I-component via ramp after P 2680 /subindex 1 |

| (2) | PRC_CTRL_FREE | Bit 2-7 Reserve |

| P2882 | CON_PRC_StatWord | Status word of the process controller |

| (0) | PRC_STAT_On | The value of bit 0 indicates whether the process controller is switched on |

| (1) | PRC_STAT_ResetIReady | Bit 1 signifies that the I-component of the process controller is reduced |

| (2) | PRC_STAT_FREE | Reserve |

| P2683 | CON_PRC_REFSEL | Selection of reference source |

| (0) | USER | User reference of P 2684 |

| (1) |

RPDC |

Reference of planetary gear |

| (2) | ISA00 | Reference of analog input ISA00 |

| (3) | ISA01 | Reference value of analog input ISA01 |

| P2684 | CON_PRC_REFVAL_User | User input of process control reference |

Tabelle: Process controller parameters

Copyright © LTi DRiVES GmbH, Januar 2013, ID-Nr.: 0842.26B.1-00 DE